How To Fix Pinwheel Roller Marks

What are Pinwheel Roller Marks?

Pinwheel roller marks also known as Pizza Cutter marks are a common issue raised from users who print on to high release (HR) sublimation papers. Including our own Fabric HR paper as well as TexPrint XPHR and other well known brands.

On Epson desktop printers used for sublimation printing the final set of rollers that the paper passes through are known as ‘pinwheel’ rollers. They are small; around 3-4mm in diameter and are a gear shape consisting of spiked points (very much like a pizza cutter – hence the alternative name for the issue)

Examples of Pinwheel roller marks are shown below:

Why do Pinwheel Roller Mark occur?

The marks occur more commonly on high release (HR) sublimation papers. This is because high release sublimation papers have a specific coating that is designed to hold ink as close to the surface of the paper as possible. Furthermore the coating is extremely soft and does not allow the ink to fully dry.

Both these attributes allow the paper to release more ink during heat pressing resulting in a better quality transfer on fabric based substrates and surfaces.

But in doing so this does mean the paper is easily scratched or marked by the pinwheel rollers on the printer (because the ink is not fully dry and is held closely to the surface)

What papers can suffer from Pinwheel Roller Marks?

Typically high release (HR) sublimation papers suffer from pinwheel roller marks. There are a number of brands and papers that suffer. Within our range; Ink Experts Fabric HR can suffer, but our other papers do not (Fabric HR is our only high release paper)

Do Pinwheel Roller Marks show after transfer?

Usually high release papers are used for sublimation on to fabric based substrates (t-shirts, cushion covers, tote bags, aprons etc) with these types of surfaces the weave of the fabric and imperfect nature will ‘hide’ most or all of pinwheel roller marks.

Therefore although they can look bad on the paper the final transfer is usable and shows no imperfection to the printed design.

We recommend our own Fabric HR paper for use on fabric based substrates for this very reason.

Here we have transferred on to linen pencil cases without issue:

Here we have transferred on to polyester t-shirt material without issue:

How to remedy and reduce Pinwheel Roller Marks

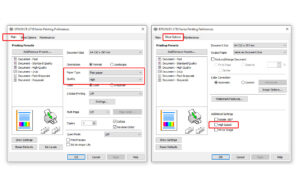

Typically our advised settings for our own Fabric HR paper work to reduce the risk of marking or scratching of the media. We advise the printer is set to the following settings via the print driver:

- Paper Type – Plain Paper (reduces the amount of ink being applied to the paper)

- Quality – High (ensure quality remains reliable and consistent)

- High Speed Print – Unticked / OFF (reduces speed in which the printer prints allowing extra time for the ink to dry)

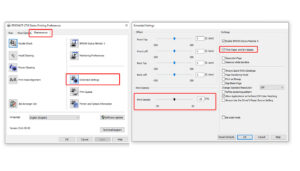

However additional settings can often be required:

- Thick Paper and Envelopes Mode – Ticked / Applied (this increases the platen gap on the paper feed rollers reducing pressure from the rollers on the paper)

- Decrease Ink Density – reduce the ink density by 15-20% using the ink density slider (this reduces the amount of ink applied to the paper allowing the ink to dry quicker)

Both of the above settings can be found in PRINTING PREFERENCES > MAINTENANCE > EXTENDED SETTINGS

These can be applied to most of the Epson printer range, but some settings can vary depending.